At first glance, hydraulic hoses and rubber tubing will look similar as they have similar characteristics with flexible or rubber elastomer based construction that transport fluids. But performance of both hosing differs a lot and they're on two completely separate playing fields. To have deep understanding of differences between both means that you will stay protected from devastating system failures. Let’s take a deep dive into what makes them different, and why it matters that you select the proper one.

Both rubber hoses and hydraulic hoses are widely utilized in industrial setups. But there are vital differences between the material build of both the tubes or hoses, and this makes them suited to different applications.

Rubber hoses or tubes are constructed from natural or synthetic rubber. Rubber is an elastic material and this is what makes rubber tubing so flexible and the pipes can be bended easily. The advantage of such a flexible nature is that the rubber pipe can be bent to fit a tight space and navigate around obstacles. Rubber hoses are commonly used in both industrial and residential setups. Moreover, they are used in several applications for fluid transfer, like automotive cooling systems.

Rubber tubing is cheap to manufacture and easy to produce since they have a simple design. However, they only function well in environments where the pressure of the fluid is medium or low. High-pressure flow damages rubber and rubber pipes can burst if subjected to high pressure.

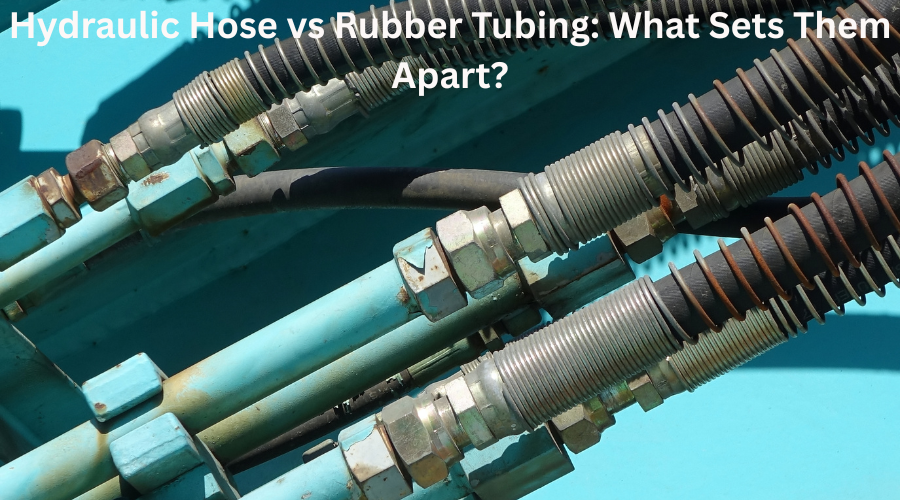

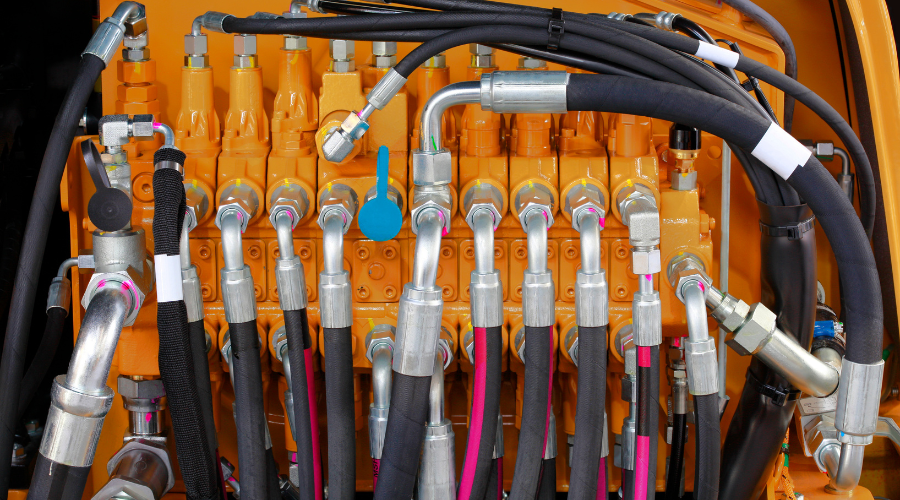

Hydraulic hoses are used in harsher environments due to their more robust construction. They have a multi-layer construction made up of several layers. The innermost layer is made of thermoplastic or synthetic rubber. The reinforcement layer is made of wire or fiber. At the same time, the outermost layer consists of rubber, which is abrasion-resistant and can withstand exposure to oil and chemicals.

The construction and design of hydraulic hoses give them the capability to withstand high fluid pressure. Such pipes are used in hydraulic systems of construction equipment and aircraft. Since they can tolerate high pressure such hoses become really useful in transporting pressurized fluids accurately.

How pipes handle fluid pressure becomes really important during special applications. If we consider both hydraulic hoses and rubber tubing options, both of them have their strengths and weaknesses regarding pressure handling.

Rubber tubing can manage low to medium fluid pressure increasingly well. These pipes are elastic so they can stretch a bit when the water pressure rises but too much pressure can make them burst. So rubber tubing is widely used in applications with low water or air pressure, like residential garden hoses or air compressor pipes.

For heavyweight applications, hydraulic hoses are a much more suitable fit for the job. They can handle a much higher pressure compared to rubber tubing. Their multiple layers make the hose tough enough to tolerate high pressure. The multi-layer design has a flexible inner layer and hen several reinforcing layers made of fiber, and finally, a tough outer layer that safeguards the pipe against external damage. Such a design gives a high degree of pressure resistance to the hydraulic hose, making them a perfect fit for hydraulic systems of construction machinery. These pipes should be tough enough to transport oil or hydraulic fluid to parts of the excavator or bulldozer with a pressure that makes these machines move and function.

The handling of pressure makes both these types of tubing suited for different sectors. Rubber hoses are utilized more in the residential sector and come handy in daily tasks around a household. On the other hand, hydraulic hoses are more useful in the industrial sector.

Even though rubber hoses are not as strong as hydraulic, they can still prove to be quite tough and long-lasting if used for a suitable purpose. If a rubber hose is used for watering purpose around a house then it can last for several years provided that it is used not too roughly. Rubber hoses do not tolerate extended exposure to chemicals or high temperatures really well so they can become damaged and cracked which will definitely shorten their usage life.

Hydraulic hoses are much sturdier than rubber hoses and can endure inclement conditions. They are intended for repetitive exposure to tough conditions as found in construction and manufacturing.

Budget becomes a really important factor in any pipeline or hosting setup, and if you are thinking of saving money, then rubber hose is a better choice since it costs significantly less than hydraulic ones. It has a low manufacturing cost and suits perfectly well for small-scale applications where you do not need to spend a fortune.

Compared to rubber tubing, hydraulic hoses are expensive. The main reason is that their material construction consists of several materials. But they are well worth the investment since they are used in important industrial applications.

So, you want to make a rask more productive by choosing the right tubing? Then, your approach should be to consider for what purpose you will be using the tubing.

If you are working on a small-scale project or your project is related to household application, then a rubber hose is a suitable option. Such hoses are quite efficient for low-pressure tasks like watering the garden.

Nonetheless, in an instance where there are heavy duty jobs that involve the use of heavy machinery then using a hydraulic hose is inevitable. These hoses are specialized to prevent the harsh conditions.

Having an accurate idea about the pressure of the task is vital. Rubber hoses cannot withstand high pressures and will likely burst. Another factor to consider is the nature of the fluid. Thin fluids like water or air may exert a small pressure and suit rubber tubing, but for oils and chemicals that have a thicker consistency, you will need to get a hydraulic hose.

Even though hydraulic hoses and rubber tubing have visual similarities, they're built for totally different jobs. Hydraulic hoses are tough, reinforced, and made to handle really high pressure—perfect for heavy-duty equipment. Rubber tubing, on the other hand, is crafted for low pressure. It's great for fluids like moving air or water, but once the fluid nature changes a more robust piping is required. Bottom line? Make the right choice for your setup so everything runs safely and smoothly.

Q1: How does hydraulic hose differ to rubber tubing?

A: Hydraulic hoses are made stronger and can carry high-pressured fluid as seen in hydraulic transmission systems whereas rubber hose is the usual tubing that carries low-pressured systems such as air, water, or liquids.

Q2: Can rubber tubing substitute hydraulic hose?

A: No, rubber tubing lacks the strength and pressure resistance required for hydraulic systems and can fail under pressure, posing safety risks.

Q3: Why are hydraulic hoses reinforced?

A: Hydraulic hoses are reinforced with braided or spiral layers of steel or synthetic fibers to withstand extreme pressure, high temperatures, and mechanical stress in demanding environments.

At first glance, hydraulic hoses and rubber tubing wi...

READ FULLRubber seals are components that are used to prevent different ...

READ FULLNumerous industries rely on hydraulic hoses without e...

READ FULL